What is FOODPROCS-Lite?

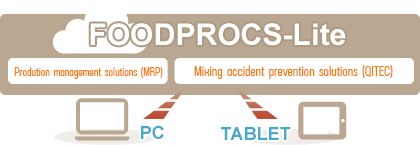

By narrowing down the essential functions of the Production Management System – FOODPROCS used in Kewpie Corporation, it is a system which is easy to implement to your factory.

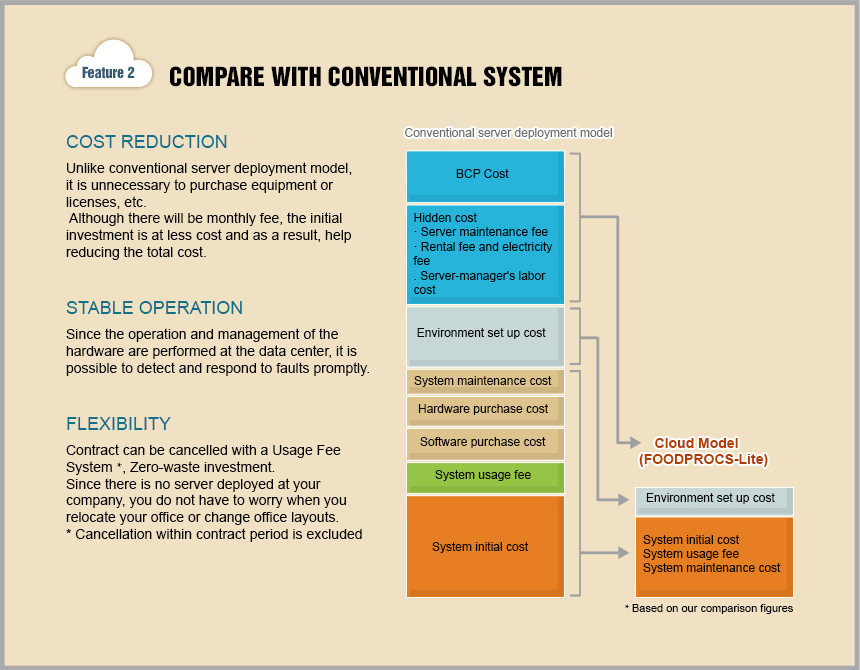

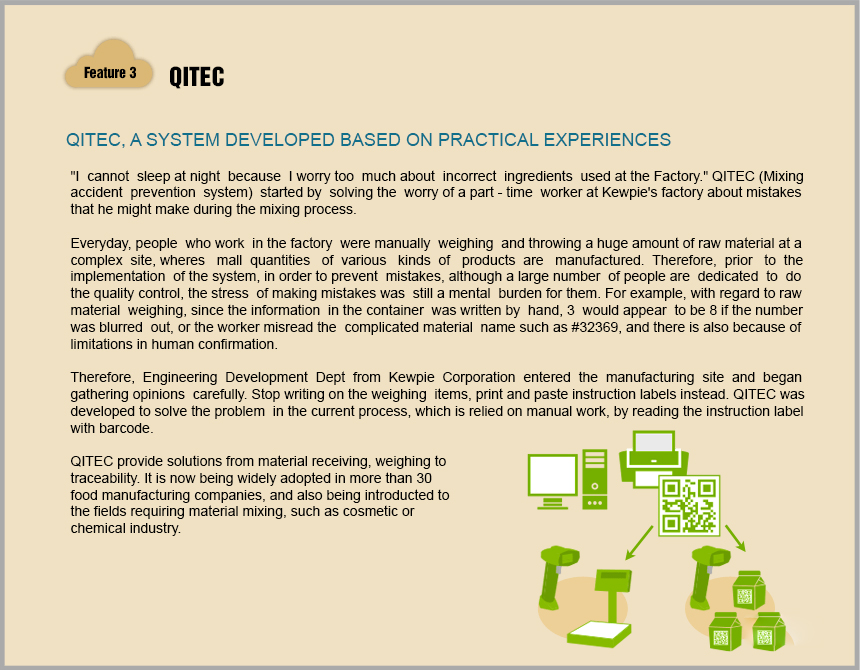

We have customized FOODPROCS, a system used in 90 domestic and foreign factories of Kewpie Corporation, to proudly introduce an easy-to-use, easy-to-implement system, FOODPROCS-Lite. And by bringing the essential management functions necessary for factory, and Mixing accident prevention solutions (QITEC) into the Cloud service, we are able to support our clients to significantly reduce initial costs and have a better operability.

If you have any questions ragarding Production Management System, please do not hesitate to contact TO Solutions Vietnam.

028-7302-4625

Operating environment

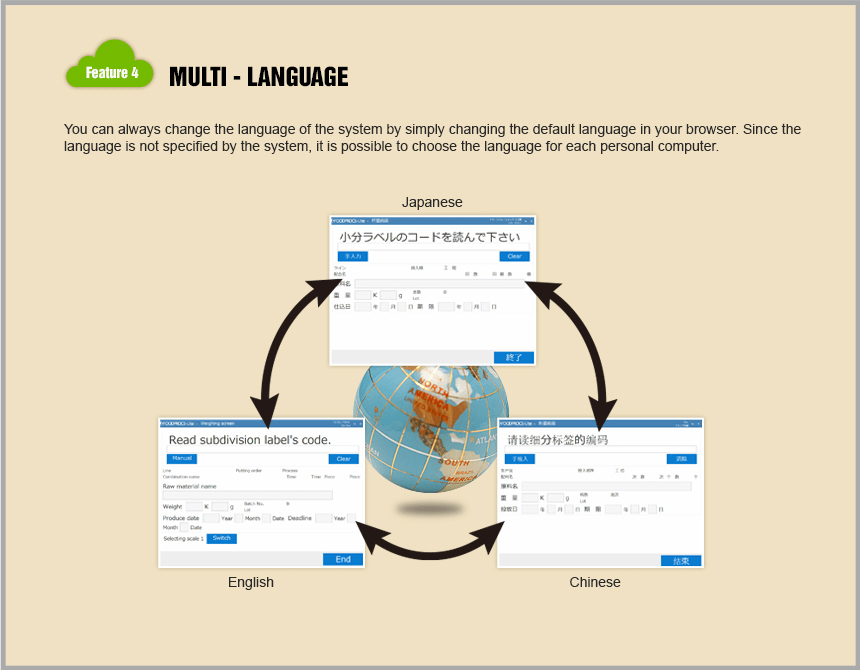

You can enjoy the benefit of Cloud services that let you immediately be able to use without being influenced by location or PC environment.

SYSTEM CONFIG. EXAMPLE

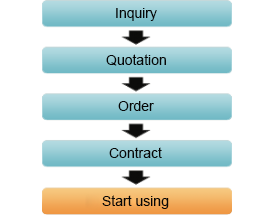

OPERATION FLOW

Estimated base on our business day.

Please inform us of the desired date of your inquiries or questions.

※ When you start using the system, it is necessary to register Master data.

※ Machine installment time does not included.

FOODPROCS-Lite Features

Since FOODPROCS-Lite was developed by narrowing down the essential functions for factory, it is possible for everyone to use it without any confusion of the operation method.

If you have any questions ragarding Production Management System, please do not hesitate to contact TO Solutions Vietnam.

028-7302-4625

FOODPROCS and FOODPROCS-Lite Case Study

Salads and food-processing company

Results after implementation:

Before FOODPROCS-Lite was deployed, it was complicated to change excel formulas of manufacturing instructions. After implementation, just by registering data master at Production Management System, it not only shorten the time to register manufacturing instructions, but also avoid mistakes.

Egg products manufacturing company FOODPROCS

Results after implementation:

Before FOODPROCS-Lite was deployed, putting data into excel is complicated and mistakes are easily passed unnoticed. There are many problems such as lacking purchase order or wrong quantity order, expired materials loss caused by over stock or wrong order, material shortage. However, with the implementation of Production management system, inventory management and ordering work became easier, and food waste was also reduced.

Pre-cooked foods manufacturing company FOODPROCS

Results after implementation:

Before FOODPROCS-Lite was deployed, since factory workers have to check the material mixing checklist in paper, and it would cause a huge mental burden for them to make sure everything is done without mistake. The waste loss when mistake occurred could reach several millions yen a year. Thank to Mixing accident prevention solutions (QITEC), the mixing mistakes cause by wrong recipe or expired materials have become zero. Food waste due to mixing mistakes also became zero

Mayonnaise and Dressing manufacturing company FOODPROCS

Results after implementation:

Before FOODPROCS-Lite was deployed, in order to do the investigation on materials quality or inconvenience in manufacturing, it took a huge amount of time to refer multiple documents. With the Mixing accident prevention function (QITEC), product tracing has become possible, making it possible to quickly extract product information or work history. Dealing with the claims from business partners has also become easier.

If you have any questions ragarding Production Management System, please do not hesitate to contact TO Solutions Vietnam.

028-7302-4625

CONTACT US